What will the post Covid-19 world look like? One area that will see a drastic change is in the number of passenger flights. Environmentally minded people welcome this, but what about workers in the industry, and what will the knock-on effect be for their families and communities? Over 80,000 workers are employed in the aerospace industry in Britain, either making aircraft, aircraft parts or in research and development. Now is the time for a plan to convert spare capacity to sustainable and socially useful production. We need a plan! Well, fortunately, there already is one.

By Ritchie Hunter

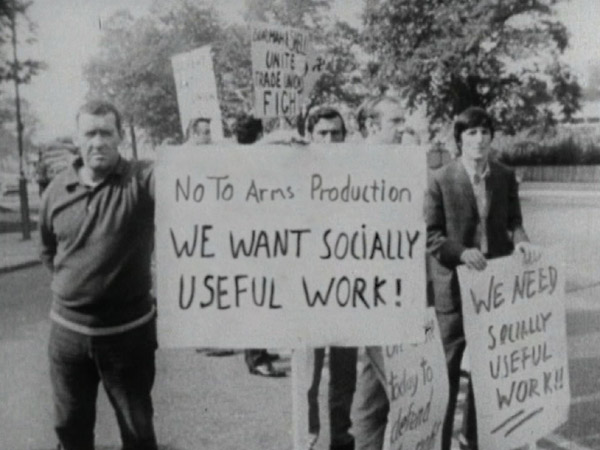

The Lucas Plan was a bold endeavour by workers to swap from designing and making weapons of war, to socially useful products such as wind turbines, kidney machines and electric cars. Their ‘bottom up’ approach is needed today if the world is to be re-shaped after the pandemic and as we tackle the Climate Crisis. It challenged the wastefulness of Capitalism, while providing meaningful jobs and services.

In the early 1970s unemployment rose to levels not seen since the 1930s, as Britain’s manufacturing industries moved abroad and those that remained started to restructure with new technology. Under pressure from trade unionists the Labour Government proposed a limited nationalisation. Tony Benn, the Secretary of State for Industry, told Lucas Aerospace Shop Stewards that their company was not to be included in this state intervention, even though thousands of job cuts had been announced. The Shop Stewards from 17 sites formed a combine committee, with the aim of designing socially useful alternatives to replace production of mainly weapons-focused products of Lucas. This was the Lucas Plan.

These plan went one step beyond the conventional limits of “defensive” trade unionism. Strikes and occupations up to this time had been about retaining jobs as they were. A vision of a different society was put forward here, one where new technologies were used to bring benefits to workers and not to harness them ever closer to production and profit by deskilling their work.

Here workers were to be involved in all stages of the process ‘by hand and by brain’. The Plan advocated a “human-centred technology”, designed to maximise the use and development of workers’ skills, thereby fostering their development as people, by giving them pride in their work and abilities.

The Lucas Plan challenged the managers’ right to manage, the elite’s right to structure society and the central myth of capitalism, that workers are incompetent, and don’t have the skills to run things. Actually this type of plan won’t work unless it’s the workers themselves who control it all.

One of the questions raised by The Plan is how you define ‘socially useful’. It’s no use replacing one product with another, if the problems of resource depletion and pollution persist, only somewhere else, or if you are still making profits for companies. So how something like the electric car is built, what materials are used, or where the energy to drive them is from, must have this ‘social’ factor as well.

The Lucas Plan’s most important lesson for us is one of control. Remember it was under a Labour Government that the plans were dashed, and although John McDonnell embraced a new version of the plan, Labour would’ve come up against the resistance of the elites to any loss of control of production.

John Maynard Keynes said in 1930 that it was possible to work just 15 hours a week, and produce all that we need. Technologies can bring tremendous benefits to the human race, and they can help solve some of the ravages of the Climate Emergency. But as technologies advance, control is being taken away from workers.

We need to take control, to build alternatives ourselves, in workplaces and communities. We can’t rely on the profit driven system to solve any of the worlds problems.

When Peace Breaks Out – LucasAid!

John Routley was a member of the Lucas Aerospace Shop Stewards’ Combine Committee which designed the Lucas Plan. This is an extract of an interview with Ritchie Hunter from February 2020.

From our point of view it wasn’t just about making socially useful products, but how they were made. We wanted to maintain the workers’ skill-set. So we looked at the manufacturing process of the products. We weren’t aware at that time about climate change. It became an issue in different ways when we started to design wind turbines. We realised the difficulties in outlying areas where they just couldn’t get electricity from the grid. Transport was another area where, although an electric vehicle was our goal, the batteries just weren’t available then in the mid 70s, so we designed a hybrid vehicle with a power pack. The concept was that this would encourage the company to invest and develop this industry. So there were longer term objectives, and we recognised the need to reduce petrol consumption anyway.

We saw (in our factories which made fighter aircraft) that at some point ‘Peace could break out’ and then there would be nothing to fall back on. What we wanted to do was set up joint conversion committees with the management to look collectively at what other products we could make; what would be sustainable. We recognised that they weren’t going to stop making fighter aircraft overnight. So we wanted to engage with the company to see what else we could make.

Obviously we wanted them to convert to socially useful products, but we had to try and win the argument that this would be good for their business. So we said to the company “Why not switch production to Kidney Machines as well as what you are already making, and there’d be no need for ‘Down Time’.”

But the company replied “It’s not your place to get involved in developing any new ideas. Leave it to us to sort this”

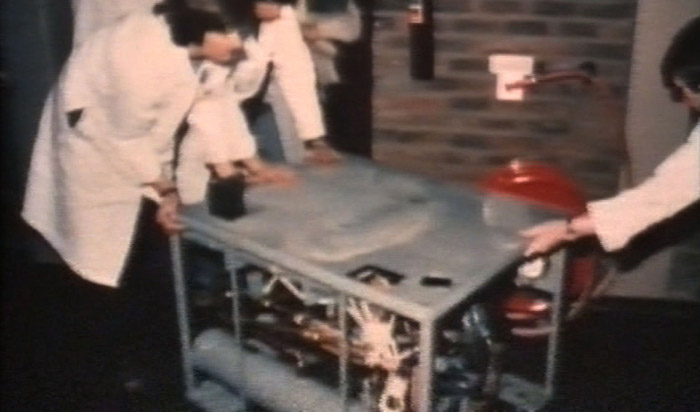

We’d been stopped from working with universities, such as Warwick, because Lucas’s had told them “If you work with the Shop Stewards then we’ll pull your funding.” The company had a big influence on who we could work with so we approached the Polytechnics. We’d already done this to develop the Road/Rail Bus. We used the expertise and the ready availability of their research students to develop products such as an electric car, the iron lung and the heat pump [see below]. We used the students for design as well as marketing. It was a real time, real life challenge for them. Other things developed from this and interest in the plan came from around the world. It came from China, across America, all through Europe; it went Global. I even worked with The Eritrean Revolutionary Group who wanted to convert MIG Fighters – a real swords into ploughshares – and looking how we could use the fuel from these for cooking.

The plan’s success was that ideas came from the bottom up, from the workforce. The ideas came from individuals who had issues in these areas. We had this one guy who wasn’t really bothered about the plan, wasn’t bothered about alternative products. But then he heard about the potential heat pump, and he was suddenly like “I really want to get involved in the design process, I want to see if this will work. If we can reverse the refrigeration process so we get warmth out, with low emissions, which is cheaper. Look at all the houses that could be kept warm at a much lower cost using the cold in winter. The colder it is the warmer we can get!”. So people within Lucas were inspired for different reasons. Some of the medical ones were because family members were ill. And when you have the workforce brought in to something because it’s their ideas, you can understand why not just the management but the trades unions feel threatened, but all we wanted to do was say “you don’t need to make us redundant, we can make this instead, and this will be of greater benefit than what we are currently making.”

One of the senior Shop Stewards was Mike Cooley. He became a guest professor at universities. He was a brilliant engineer in his own right, and one of the main brains behind solving some of the technical challenges we faced. One of the ideas he put forward was a “human-centred technology”, designed to maximise the use and development of workers’ skills, not just looking to produce socially useful products, but at how we produced them. I’m going back quite a long time to when he stated that one of the greatest threats we have to our planet, never mind our jobs, will be Artificial Intelligence. At some point AI won’t need man, it will just take over. I believe Stephen Hawking said very much the same thing. Once you develop an intelligence that is cleverer than you, then that intelligence will take over from you and make you redundant, not just in jobs but in everything.

Communities don’t realise the impact that the closure of a factory will have on the surrounding area until it happens. We had ideas of localised conversion groups to help develop the educational programme needed to get the message into the community. “Do you realise that if that plant shuts down, those two supermarkets won’t be needed. Your bus service will go, because it’s only there to get people across to the factory. People using it to get their children to school and pensioners going to and from the hospital will find it’s gone. Your local pubs will shut because workers won’t be going there to drink; cafes or sandwich bars go; your social life will go. And then the train station which served the factory is no longer there.” The knock-on effect to a closure is incredible.

For example if Barrow shipyard shuts the whole community shuts, because that’s all there is there – it’s a like a 36 mile cul-de-sac. And it’s hard to get your head round this, that they keep plodding on even though they’ve seen thousands of jobs go. At some point they will get to the point of no return. There’s a lot of work gone into Barrow over the years to support them, but the people there are the only ones who can develop a strategy and make it work.

This change can’t be imposed. What we can do is get the message out to help with the education part of it. Communities have to come up with plans themselves.

Some of the ideas put forward in the Lucas Plan

150 product ideas were put forward by the workforce. From them, products were selected to fall into six categories: medical equipment, transport vehicles, improved braking systems, energy conservation, oceanics, and telechiric machines, which remotely carry out tasks under human control in environments hostile to humans.

Specific proposals included, in the medical sector, an expansion of 40% in the production of kidney dialysis machines, which at that time were being manufactured on one of the L.A. sites. The Combine ‘regarded it was scandalous that people could be dying for the want of a kidney machine when those who could be producing them are facing the prospect of redundancy’. In the energy sector, proposals included the development of heat pumps, solar cell technology, wind turbines and fuel cell technology. In transport, a new hybrid power pack for motor vehicles and road-rail vehicles. Later, the Combine produced a road-rail bus, which toured the country.

https://lucasplan.org.uk/story-of-the-lucas-plan/

Iron Lung: A lightweight machine that could fit on a bed. Designed by John Routley

The pilotless helicopter: In other words a drone

Heat pump: A sort of reverse refrigeration. It took cold air from outside a house and reversed the process to make warmth inside. The colder it got, the more warmth it produced. Designed at the Burnley plant.

Power Packs: Unique hybrid power pack which could be used in cars, coaches and trains, and could work relatively maintenance free for about 20 years, reducing energy consumption by about 50%.

Further reading/viewing

‘The Plan that came from the bottom up’ trailer: https://www.youtube.com/watch?v=DoUPnZpzNOI

Mike Cooley ‘Architect or Bee?’ The Human Technology Relationship

Images from Steve Sprung – producer of ‘The Plan that came from the bottom up’

Permalink

I’ve been to film shows and speaker panels on the Lucas Plan – it’s always inspiring. And it’s being updated for the our crisis-riven Covid World, now hurtling and hustling its way to human redundancy and the destruction of our planet. We need the Lucas Plan now more than ever – workers in control along with communities for the production of socially useful products not for profit. Let’s break through the fetishised world of careless commodity production for the nuclear enrichment of explosively and dangerously rich hoarders in a capitalist system that exploits us all to own us. All power to us!